What does XR4industry do?

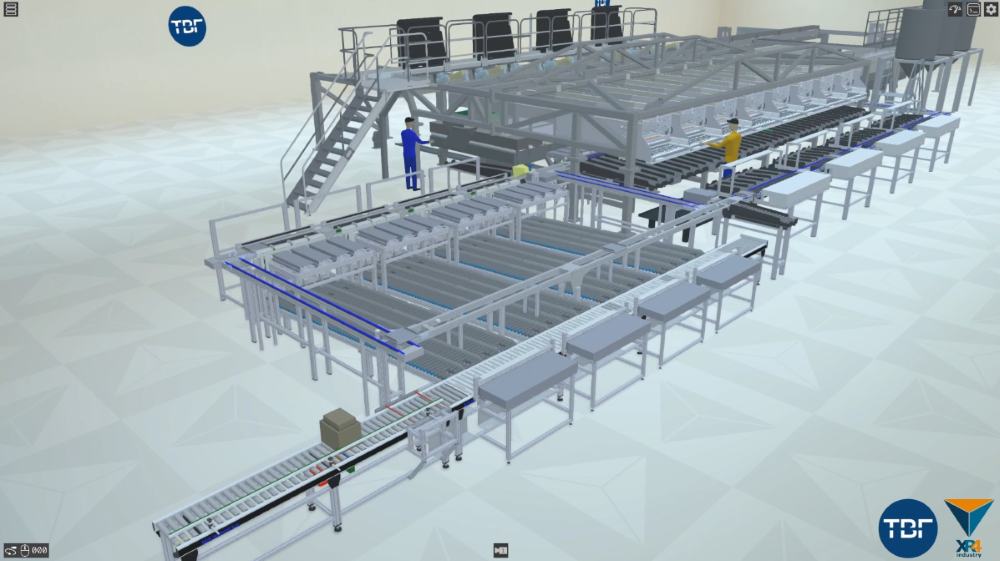

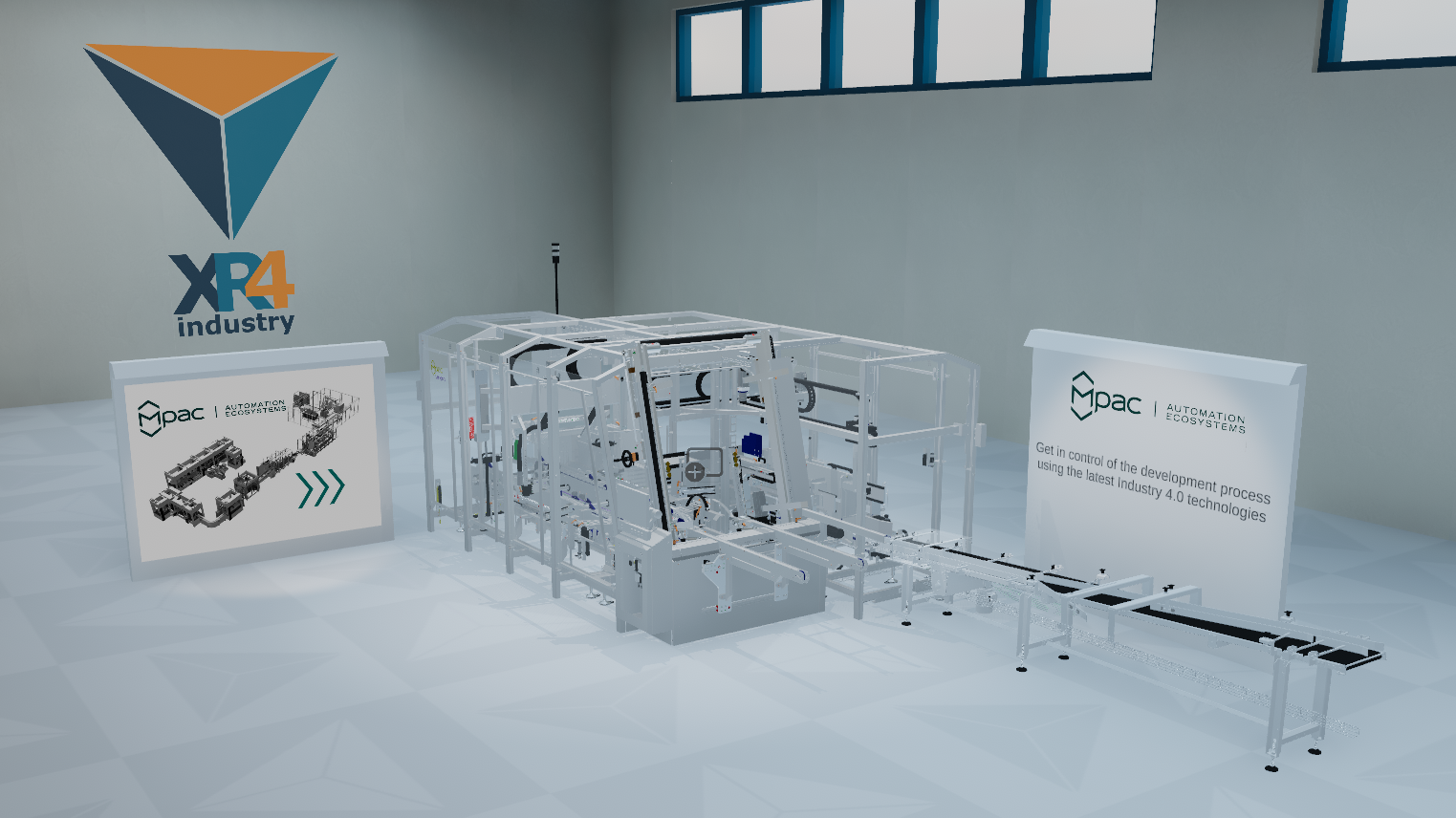

XR4industry is a rapidly growing startup based in Wijchen, specializing in the development of simulations for the validation and virtual commissioning of machines, production lines, and robotic solutions. These interactive simulations are commonly referred to as digital twins. Our simulations enable companies to reduce the development time of new machines and concepts . With our unique approach, we make digital twins cost-effective even for small businesses, enabling them to use this technology that was once primarily available to larger enterprises.

Our customers have the ability to thoroughly examine their designs for errors and inaccuracies before the physical production of a machine, thanks to our simulation. Additionally, programmers can develop and test machine control by connecting the simulation the PLC. These simulations are also employed by our customers to more clearly present the machine to their end customers during the sales process. The various departments, including engineering (3D engineers and PLC programmers), sales, and training, can all utilize the same simulation environment.

If this sound to good to be true, or if it sounds like the effort will not be worth it. We’d love to show you how our young and innovative company can make these simulations viable for your company. For instance, we can create the digital twin for you, allowing you to immediately use it for developing and testing PLC software without you having to learn how to make these simulations yourself.

Configurable Twin

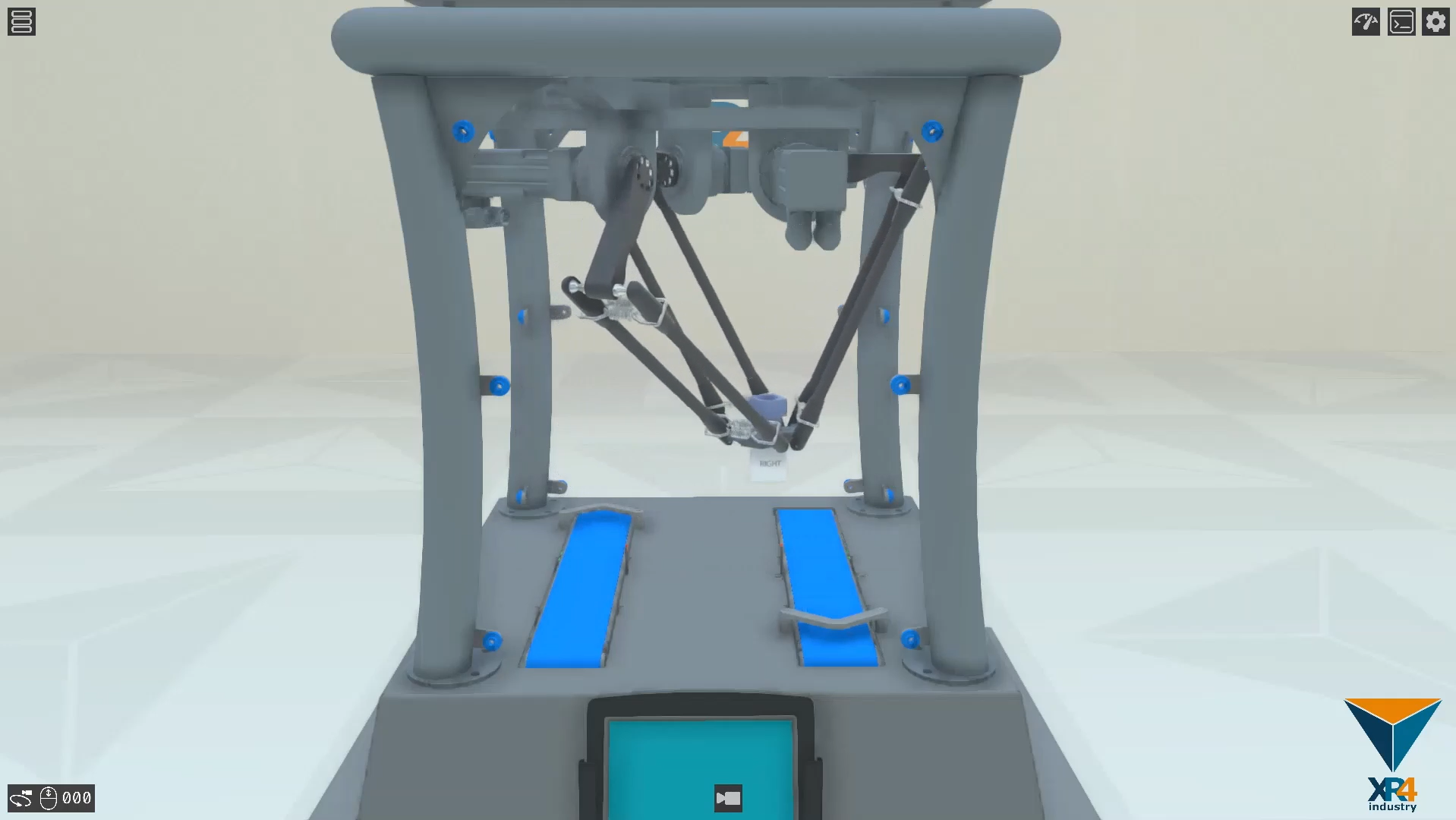

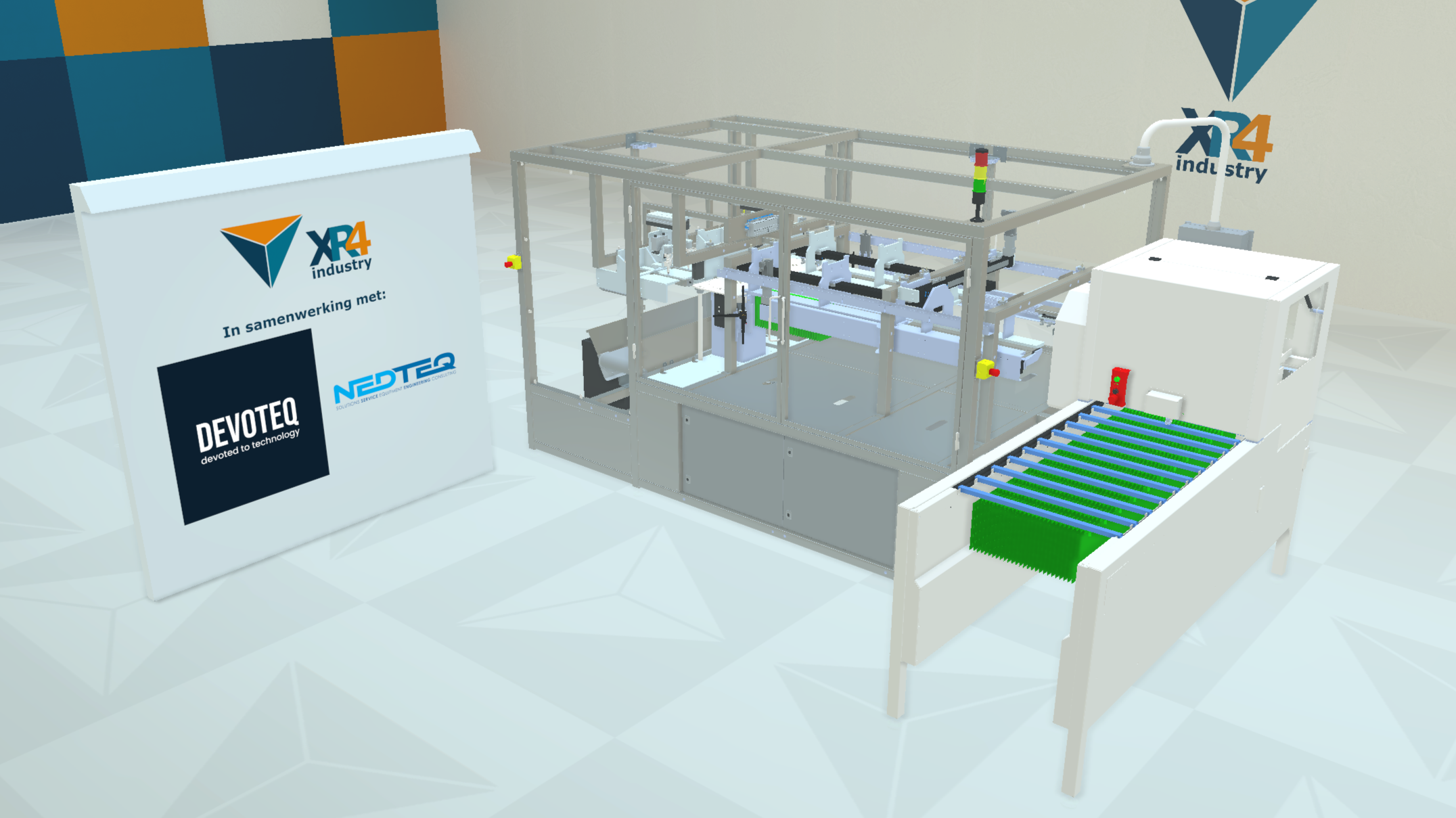

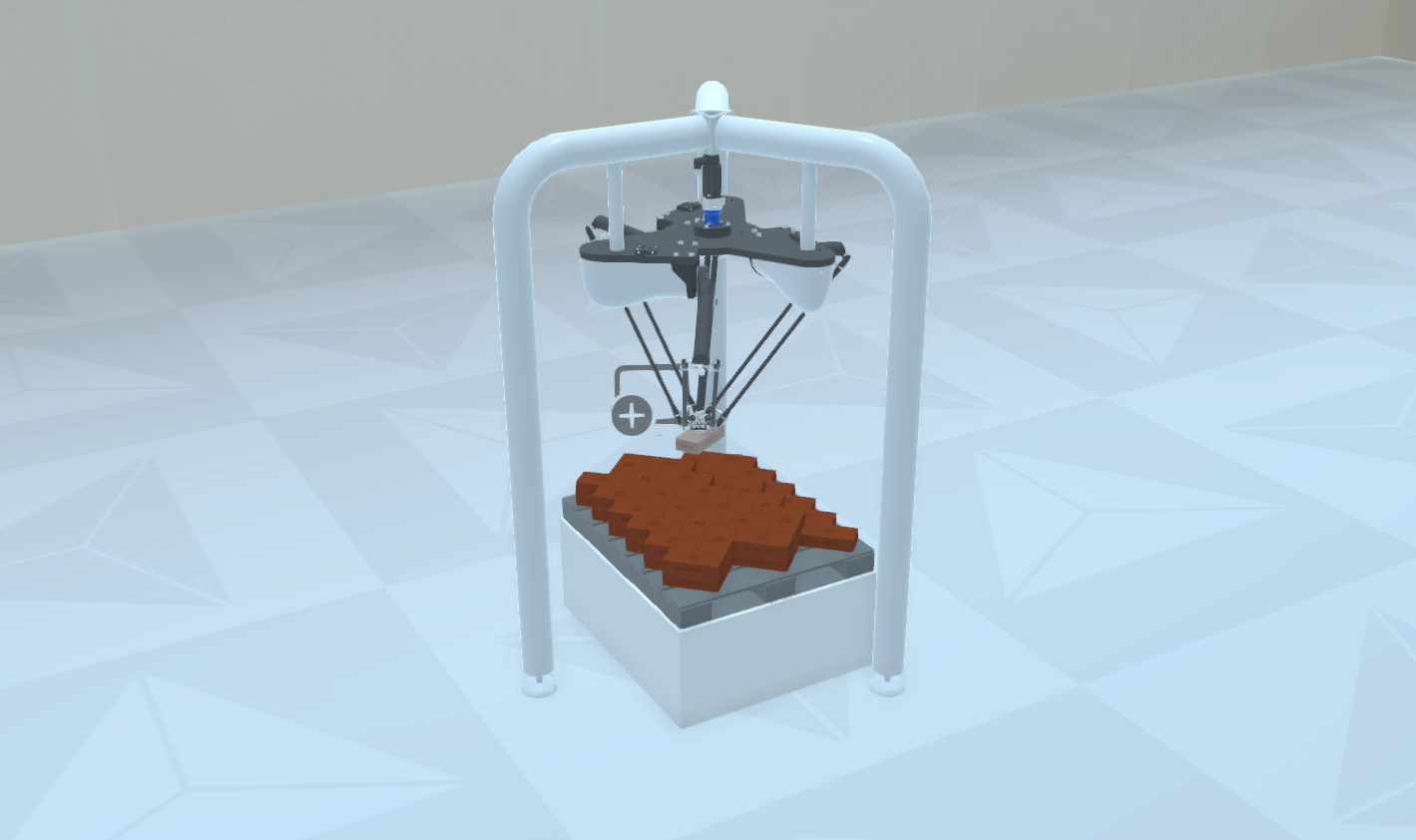

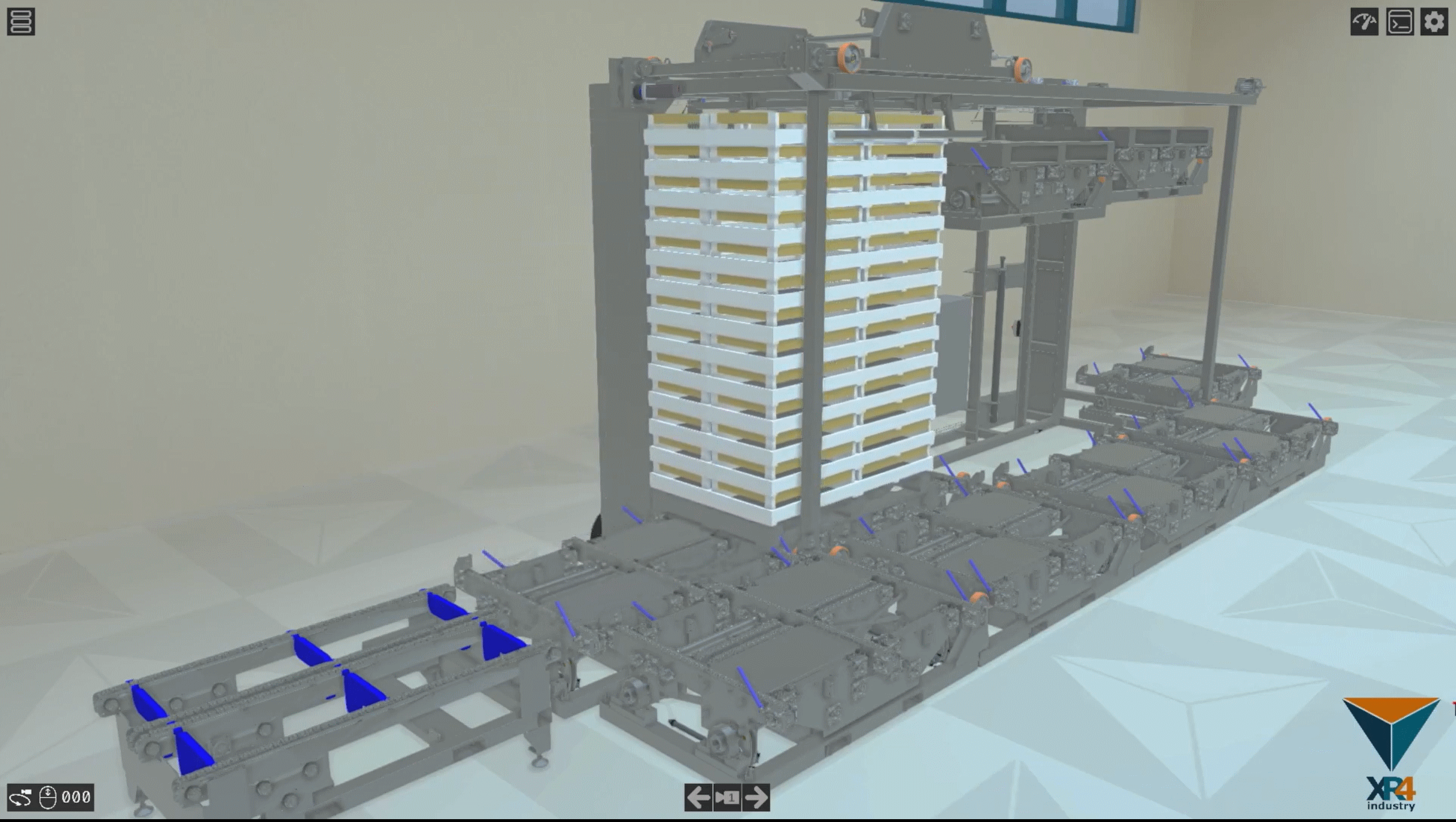

XR4industry has developed a new software product for machine builders, concept engineers, and system integrators in industrial automation and robotics. This product enables companies to rapidly and intuitively work out 3D concepts using standard or custom components. Users can choose from various dynamic elements like robots, conveyors, and sensors, and can also incorporate custom GLTF and URDF files to create the desired concept setup. The same software can be utilized by sales teams for presentations, engineers for final design validation, and PLC programmers to validate their programs. Additionally, a significant portion of the commissioning process for the new machine or robot setup can be done virtually within the software. This integrated approach facilitates a seamless transition from design validation to the programming and commissioning stages.

Users can choose the components they want in their configurable environment. These can be either standard components or customer-specific components, as long as there is a 3D model available. Examples include a delta robot, a single-arm robot, a SCARA robot, a conveyor belt, a vision system, infeeds, sorting bins, cobots, and various sensors. All these components can be utilized to quickly develop and test an automation solution. In addition to these standard dynamic components, users can also import their own URDF and GLTF files.

Once the configuration is done, movements of the components can be specified. This can range from simple movements from point A to B to a complete control program based on sensor input. This simulation can be used in discussions with clients as a visual aid to clearly convey concepts. Moreover, it can be employed to provide estimates of throughput and identify potential bottlenecks in the system.

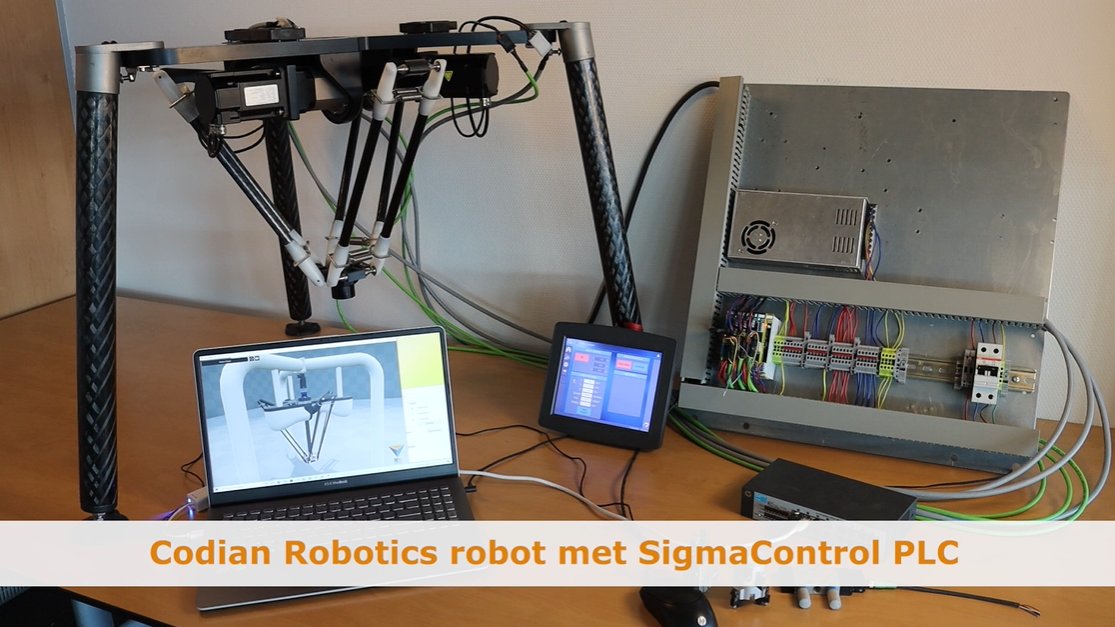

After the sales and concept engineering phases are completed, the same environment can be utilized by the engineering department to mechanically and dynamically validate and improve the design. Once the engineering team approves the design, the PLC (Programmable Logic Controller) programmer can also leverage the same environment. The programmer can link the PLC to the Configurable Twin and test and commission the behavior of the setup. This integrated approach facilitates a seamless transition from design validation to the programming and commissioning stages.

How can the 3D designer utilize our software?

Our simulations empower companies to more thoroughly validate the design of new machines. The visualization method provides new insights into the design compared to a standard 3D design software. Additionally, movements can be added to the design so that all machine movements can thoroughly be checked for errors. All these tests are intuitive and do not require experience with 3D software packages.

Freek Hartman, Managing Director at Codian Robotics:

“When I use Virtual Reality to look at my design, I get more realistic insights before I get to see the first prototype. This shortens the development process a lot.”

There are two ways of viewing the machine. Through VR glasses (true size) and on a regular computer.

How can the PLC programmer utilize our software?

After validating the design, the components can be ordered. The time between completing the design and building the machine can be utilized to program the PLC or controller if companies use a digital twin. The programmer can link the simulation to the controller through an OPC-UA connection or a direct connection, depending on plc supplier, and subsequently analyze the machine’s behavior before it is built.

Our software is based on the Unity game engine and the digital twin always starts with the 3D drawings provided by our clients. This approach, combined with the development of our own software, enables us to set up simulations more quickly than the industry standard. Additionally, with our software, clients are not required to program anything unless it is desired. We can deliver fully configurable environments compatible with all PLC brands, robot suppliers, component providers, and CAD packages. Our software is entirely open, allowing clients to build custom applications to control or utilize the simulation in other ways.

To facilitate the PLC programmer in testing their software on the simulation, our simulations can communicate in real-time with the PLC. Additionally, the simulation can update in real-time without compromising deterministic properties.

Simulating the product handling in machines is also possible. This allows companies to test various scenarios and products before a physical machine is produced. This helps reduce surprises during commissioning, startup, Factory Acceptance Testing (FAT), and Site Acceptance Testing (SAT).

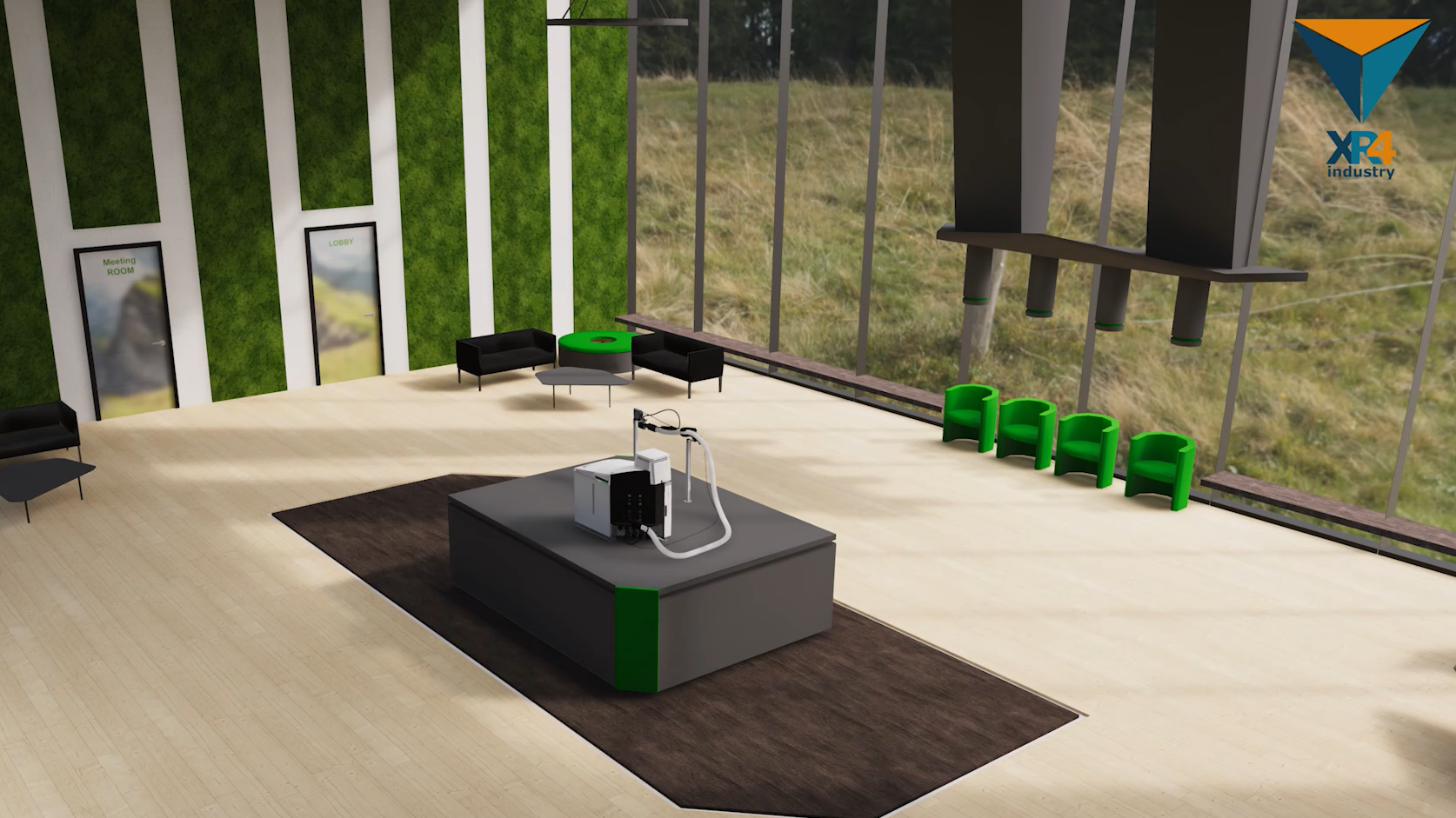

How can the sales team use our software?

Our software, which aids engineers and programmers during development, can also be utilized by the sales and marketing teams. Customers can be taken through their yet-to-be-built machines interactively, preventing miscommunications and generating excitement. Sales teams can virtually showcase the entire range of machines they offer, highlighting the differences between models. Marketing can use the software to generate visuals of machines, both existing and upcoming, in static or dynamic presentations. Additionally, the ability to hide confidential components provides a secure way to virtually present machines at trade shows without the risk of unwanted competitor observation.

Ariane Buining, Sales & Marketing Director at Codian Robotics: “We always invited people at an expo, or to our Experience Centre in Ede. There, we can show all the details and differences between our robots. Since we have got the VR showroom, we can also do this through Teams.”

Within our software, two ways of viewing the machine are possible. Using a VR headset brings the machine to life, allowing customers to view it at true scale and walk through it. Alternatively, without a VR headset, presentations can be conducted on a computer with the ability to navigate through the machine using the keyboard. While somewhat less immersive, this option is highly suitable for remote presentations or shorter sessions due to its accessibility.

Projects

The Team

Wessel Poldervaart

Software Architect

Tim van den Berg

Software Developer

Thijmen Lemmens

Software Developer

Sjoerd Meeuwsen

Sales Engineer

Roeland Brugman

Business Developer

Johan Reijers

Managing Director

Bas Kersten

Test Engineer & Physics Specialist

XR4industry was founded on a collaboration between three areas of expertise: An autodidactic programmer, a perfectionistic 3D-animator and a research and product developer with over 25 years of experience in the more traditional industries. This unique collaboration, through the small scale and diversity, makes it possible to apply the newest techniques in the industry in an affordable manner.

3D visualisations are becoming more important with the day. More and more companies can make huge gains by a detailed virtual rendition of their products. A mechanical engineer might want to check and test their design early in the development process. Or the sales department who can present these designs on expos or through a video call using 3D.

XR4industry is a new company who uses several virtual reality techniques to make these types of 3D renditions possible for businesses. These techniques were developed in the gaming industry, and continue to improve at a rapid pace. XR4industry follows these developments, and keeps implementing these techniques into their own products. Several of these techniques are being tested in a practical environment through a close collaboration with an industrial partner, preparing them to be used on a larger scale.

Contact

XR4industry

Bezoekadres: Nieuweweg 101, 6603 BK Wijchen

Phone: +31 24 420 0541

Email: info@XR4industry.com